PRODUCTS MBR System

Membrane Bioreactor MBR

Membrane process in activated sludge

The advanced membrane bioreactor MBR for treating municipal and industrial water are presented as the key technology for recycling and reuse of wastewater for industrial or domestic use.

The effluent is characterized by a low level of suspended solids, bacteria, viruses, and the retention of trace elements, making it an ideal system for direct download in environmentally sensitive areas.

Our experience

The latest developments of a new generation of membranes Martin more productive and less costly with advances in developing of membrane bioreactors by Martin Water Technologies Inc. , has enabled us to implement the MBR in a wide range of applications for the treatment of wastewater.

Our valuable experience gained in recent years is an added value for our customers in the design of new plants as well as modifying existing ones to improve the capacity and meet increasing performance demands.

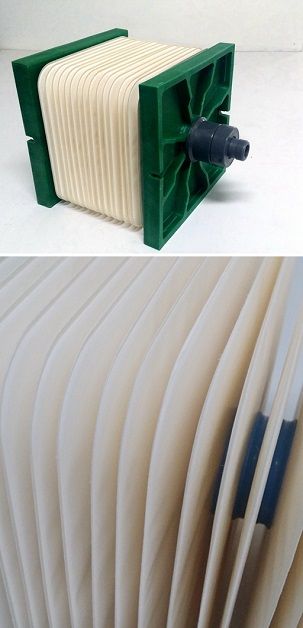

Submerged Flat Sheet Membrane

Membrane structure

Flat membranes made of PVDF (polyvinildene fluoride) as a functional layer and centeral pipe of UPVC. Permeate extraction is done by suction through the silicon tubes.

Upward air filtration

The basic principle of cross flow filtration is to allow the formation of the biofilm on the membrane surface and controlling their growth. The air carries the activated sludge that by rubbing the surface of the membrane drag the substances that form the biofouling.

Properties of Martin membrane

High permeability for water and effluent quality. Using a uniform pore size provides a high permeability and ensures minimal pore blockage.

Unique membrane structure

By the uniform distribution of numerous narrow-diameter pores along the membrane surface results in a single structure.

Improved membrane material

The use of PVDF as material of the functional layer of the membrane gives it greater mechanical strength and chemical stability

Submerged Flat membrane module Data

Model | MBR6-1040 | MBR6-1020 |

Membrane material | PVDF or PTFE | |

Membrane pore size (UM) | 0.1-0.4 | |

Center pipe | UPVC | |

End plate material | PP | |

Water inlet channel(MM) | 6 | |

Membrane elements | 132 | 69 |

Membrane area ( M2 ) | 16.5 | 8.6 |

Length(MM) | 1160 | 680 |

Width(MM) | 256 | |

Height(MM) | 256 | |

Backwashing pressure(MPA) | Gravity filtration online | |

Backwashing water amount(L/M2) | 2-2.5 | |

Backwashing time(MIN) | 18 | |

Backwashing way | Gravity filtration | |

Application | MBR ,solid-liquid separation | |

Operation mode | Negative pressure suction | |

Trans-membrane pressure (MPA) | 0.01-0.05 | |

Max-trans-membrane pressure (MPA) | 0.05 | |

Design flux ( L/H,M2) | 15-45 | |

MLSS ( G/L ) | 10-20 | |

Aeration flux ( M3/H.M2) | 0.3-0.4 | |

Operating temperature (°C ) | 5-40 | |

PH range | 2-11 | |

Resistance to chloros ( PPM,H ) | 100000 | |

Chemical cleaning Way | Gravity filtration online | |

Chemical cleaning frequency ( times/year) | 1-2 | |

Chemical quantity ( L/M2) | 2 | |

Storage condition | Keep away from fire and chemicals, storage temperature of 1°C-45°C, handle with care | |