PRODUCTS MBR System

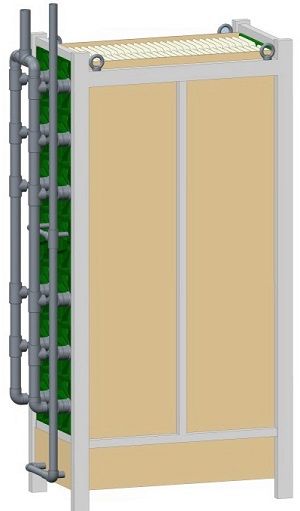

Membrane module Cassette MBR

The submerged membrane module cassette MBR is composed of membrane modules and aeration tank.

Advantage of Martin membrane module cassette MBR

1 .Advanced module design with easy installation

Different membrane modules can be assembled into different membrane reactors. It meets the needs of various water requirements and water treatment in different industry. The stainless steel frame equipped is not a must.

2.Flexible assemble

Membrane module elements are in series connection by water-producing pipes with the water inlet channel of 6mm. Membrane modules can be shortened or prolonged for different membrane reactor in order to meet the needs of different space demand.

3. Small square element, large flux, low energy consumption

Featured with a small square unit, the water from the surrounding enters membrane module and comes out from the center pipeline, such membrane module makes the water collection in a quick and efficient way and improves the utilization of water a membrane space ratio. The pressure difference across the membrane gets lower. The water output is 2-3 times of the hollow fiber membrane and 1.3 times of the normal flat membrane in MBR process. The energy consumption is 70% of the hollow membrane and 50% of the normal flat membrane.

4.Flat sheet, strong shock resistance, not easy to be blocked

Aeration rate directly affects fouling cycle of membrane in MBR system. The flexible flat membrane sheet would not be affected by its large volume. The fouling cycle of the membrane will be prolonged.

5. In-situation (on-line) backwashing and chemical cleaning with friendly working condition

The membrane module can be quickly opened up for backwashing in-situation. Chemical cleaning of the membranes is made simple in-situation as well without need of removing the membranes of the module or move the cassette reactor.

6. Cost Saving

The membrane cassette reactor can save about 2/3 compared with the normal flat membrane and 1/2 compared with hollow fiber membrane. A lifting facility for membrane cleaning is not required.

Basic Operation Term

l MBR Membrane working method: 8 minutes operation while 50 seconds short time backwashing

l Backwashing or chemical cleaning: 2L/M2.

l Backwashing time (long time): 18 minutes

l Backwashing period: Every 8-24 hours working, depends on the water quality

l Chemical cleaning time: 2-3 hours.

Backwashing Steps:

l Step 1: 8 minutes backwashing, but without aeration

l Step 2: 1 minute suction, but without aeration

l Step 3: 9 minutes non-running of system, but with aeration

Chemical Cleaning

l The chemical cleaning has to be achieved when the water output is less than 80% of designed flow or the working pressure is more than 6bar.

l Backwash the system first before the chemical cleaning

l The chemical solution has to be kept in the membrane for one hour and half. No aeration during the whole process

l Chemical Cleaning Agents: 0.5% sodium hypochlorite +1% sodium hydroxide or 0.5% citric acid

MBR Assemble and Installation

l The outlet pipes of cassette MBR has be hosed with the main pipe of the product water. No aeration or backwashing is allowed when there’s air in membrane.

l Ensure the air released valve is on the open stage before the water feeds in. Close the valve after the water feeding.

l Keep the aeration at 0.3-0.4M3/H.M2

l The backwash tank (chemical tank) has to be put in a certain place which is 1-1.2meter higher the MBR cassette, and close to the MBR system. Keep the backwash and chemical flow at 2L/M2

Standard Membrane module Cassette MBR

Model | MBR6-8E | MBR6-12E | MBR6-16E |

Application | ( MBR) (LCSS) | ||

Flat membrane module | MBR6-1040 | MBR6-1040 | MBR6-1040 |

Mem. Module Quantity | 8 | 12 | 16 |

Membrane area(M2) | 131 | 197 | 262 |

Weight ( Dry)kg | 160 | 240 | 320 |

Bulk density ( MVM2 ) | 186 | 284 | 379 |

Areation flux ( MVH ) | 39.6-52.8 | 59.4-79.2 | 79.2-105.6 |

Length | 1180 | ||

Width | 600 | ||

Height | 1770 | 2530 | 3050 |

Permeate flow(M3/D) | 48-143 | 71-214 | 96-286 |

Permeate quality | SDI < 3; Turbidity< 1 NTU ; SS< 1 MG/L | ||

Bacteria removal rate | 99.99% | ||

Remark: Bulk density is related to the depth of the membrane reactor. In the table, bulk density is for 5 meters depth of the reactor.